Vernon, BC

Wesmont Salt Centre Building B (Phase 1)

Delivering innovative, sustainable, and cost-effective solutions for BC’s evolving construction market with precision! In just four days, our expert team installed 100 panels on this build, demonstrating our efficiency and commitment to excellence.

Salmon Arm, BC

Commercial Warehouse

This light industrial 30,000 sq/ft strata warehouse is a Salmon Arm stunner! Drive-in/drive-out, 14' x 14' bay doors at both ends makes this a perfect design for any business in this industrial zoned site. This building also boasts a beautiful glass storefront, R-21 insulation, heated gas floors and 3 PH power.

Kelowna , BC

Tesla Dealership and Service Centre

Designed as a custom build, this 30,250 square-foot, one-storey, single-tenant industrial building for a new Tesla Dealership is located in the Airport Business Park in Kelowna, BC. The project featured a pre-poured concrete floor, which allowed for the installation of walls directly from the exterior of the building.

Armstrong, BC

Fieldstone Granary Warehouse

This 2024 stunning 33 panel warehouse addition to Fieldstone Granary in Armstrong, BC was created with a one-of-a kind barn wood finish. Actual barn wood was used on heated tables and then stained for a feature entrance wall that truly showcases the region in which it resides!

Kamloops, BC

Mixed-Use Commercial

Our Iron Mask Rd installation in Kamloops, BC, was a highly efficient and streamlined project for a mixed-use industrial building. Featuring 48 sleek, high-performance panels, this installation was completed in just 2 days with the help of a skilled crane team and expert on-site crew.

Scotch Creek, BC

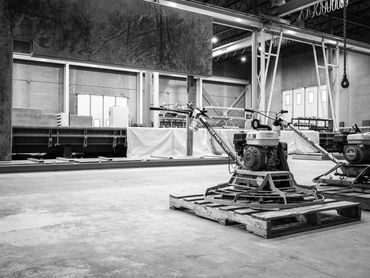

Manufacturing Warehouse

The Black Walls production and installation teams did another beautiful job on this Scotch Creek manufacturing warehouse located in Shuswap, BC. This building boasts 39' 6" high panels, 21' w x 20' h doors, a mezzanine area and a gantry crane system. Only 2 days to install the outer walls of this 40 panel beauty!

Enderby , BC

Baird Bros Shop

A custom design for this new shop addition in Enderby, BC has 18' high drive-in/drive-out bay doors for Baird Bros LTD. Lots of additional square footage (60' x 110') for heavy equipment and R-21 insulated pre-cast panels that were poured indoors for perfect curing and finishing!

Armstrong, BC

Phi Factor-Mushroom Farm

Our collaboration with Phi Factor Farm in Armstrong, BC, stands as a prime example of how we help businesses build a strong foundation for innovation. Phi Factor Farm needed a cutting-edge warehouse to support their pioneering work in sustainable mushroom farming, and we were honored to provide the perfect solution.

CONSTRUCTION PROJECTS

Durability & Strength

Manufactured to the highest standards, precast panels provide excellent durability and resistance to harsh environmental conditions, ensuring long-lasting structural integrity.

Quick Installation

Our precast panels are large, pre-assembled sections that are quickly erected on-site, significantly reducing the time needed for traditional wall construction. This efficiency cuts down on overall build time and allows for rapid installation, reducing construction timelines and minimizing labor costs, helping your projects stay on schedule.

Cost-Efficiency

By decreasing construction time and requiring less on-site labor, our precast panels can provide a significant reduction in overall project costs. With panels pre-fabricated in our state-of-the-art facility, fewer workers are needed on-site for the wall construction phase, allowing for streamlined management and quicker progress.

Engineering & Shop Drawings

We offer our clients full-service BIM Modeling, Auto CAD design and include structural engineering on every project. Let our team of seasoned construction professionals guide you through the process from the very beginning to completion of the building.

Exceed Construction Timelines

Our team can help you move in quickly and speed up your construction timeline in several ways. Black Walls precast panels are manufactured off-site in a controlled environment, allowing the construction process to begin while site preparation is still underway. This parallel work process speeds up the overall project timeline. Since the panels are made indoors, the risk of weather-related delays is minimized and ensures a more predictable schedule, especially in regions with harsh weather conditions. By reducing delays, you can start earning revenue faster.

Customization

Whether you’re looking for aesthetic designs, fire resistance, or soundproofing features, our panels can be customized to meet the unique needs of your project.

.jpg/:/cr=t:0%25,l:12.59%25,w:74.81%25,h:100%25/rs=w:370,h:278.1954887218045,cg:true)

Copyright © 2025 Black Walls - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.